- Product

-

Wear resistant protection series

-

Emulsion cleaning reduction reaction series

-

Flat silicone sealant series

-

Cable quick wear-resistant repair adhesive

-

Licheng Series

-

Lixin Intelligent Fog Forest System

-

Conveyor Belt Rapid Processing Series

-

Emergency series of leaks and spills

-

High temperature resistant protection series

-

Protective shield

Contact Us

Shanxi Beiguo Science And Technology Co., LTD

Business Consultation:+86-0354-3965688

Address: Yuci Industrial Park, Jinzhong City, Shanxi Province

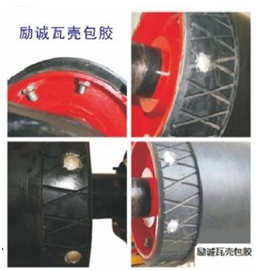

product name:Licheng LC7000 series

origin:

application:Licheng LC7010 bolted tile shell encapsulation

sales hotline:+86-0354-3965688

The bolt type tile shell coating is connected to the drum through bolts by a tile shell rubber plate, which is made of wear-resistant adhesive layer and metal layer hot vulcanized. The combination is firm, with high wear resistance and flexibility, strong tensile and tear resistance. Specially designed diamond pattern assists in the operation of the belt, doubling the friction and traction force. Can be installed on site, the drum does not need to be disassembled, convenient and fast.

Technical parameters and requirements

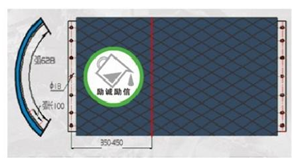

1. The tile shell steel plate is 6mm thick and 628mm wide, made of Q235A material

2. Rubber surface hardness: Non flame retardant Shore A hardness 60-75, flame retardant Shore A hardness 60-75

3. Wear rate: ≤ 160 mm3 Tensile strength: ≥ 15MPa Tensile elongation at break: ≥ 250%

Conductivity: ≤ 3.0 × 108. The peel strength between the rubber coating layer and the metal drum is ≥ 4.8kN/m.

4. The thickness of the adhesive sheet is 12mm or 15mm. The total thickness of the tile shell rubber plate is 18mm or 20mm.

5. Use M12 bolts for connection, with a radial hole distance of 100mm from the arc length; The middle screw protrusion is 5mm

6. Suitable for rollers smaller than φ 1400 × 1400.

Model | Name |

LC7010-1 | Flame retardant rubber sheet |

LC7030-1 | Wear resistant rubber plate |

LC7000-2 | Adhesive base for adhesive sheet |

LC7000-3 | Electric hand drill |

LC7000-4 | Bit |

Installation of bolt tile shell with adhesive coating

1. If it is originally a casting or wrapping roller, the rubber surface must be removed clean with a knife, pliers, and an angle grinder (with a steel wire polishing wheel);

2. Mark and drill holes at both ends of the drum according to the bolt hole size on the rubber plate;

3. Connect the tile shell rubber plate to the drum with matching bolts and tighten it in place

Tools required for installation: cleaning knife, pliers, hand hammer

Angle polishing machine (with steel wire polishing wheel), 220V power supply, stone pen, tape measure, hand drill, wrench, slag hammer.