- Product

-

Wear resistant protection series

-

Emulsion cleaning reduction reaction series

-

Flat silicone sealant series

-

Cable quick wear-resistant repair adhesive

-

Licheng Series

-

Lixin Intelligent Fog Forest System

-

Conveyor Belt Rapid Processing Series

-

Emergency series of leaks and spills

-

High temperature resistant protection series

-

Protective shield

Contact Us

Shanxi Beiguo Science And Technology Co., LTD

Business Consultation:+86-0354-3965688

Address: Yuci Industrial Park, Jinzhong City, Shanxi Province

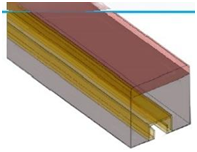

product name:Licheng LC6000 series

origin:

application:Buffer bar connection structure

◆ Easy to install

◆ Structural anti loosening measures

sales hotline:+86-0354-3965688

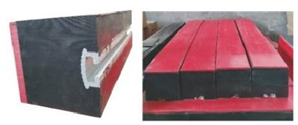

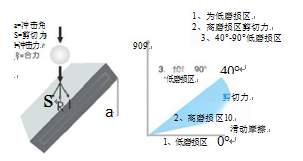

Transfer point issue in the conveying system

The impact force at the transfer point of the conveyor belt is relatively high

Traditional solution:

Install steel plates at the transfer point location, and install various I-beams and grooves on the steel plates

Disadvantages:

1. There are many safety hazards

2. Short usage cycle

3. High noise level

Effective solutions:

Common specifications, models, and parameters

Rubber overcomes hardness with softness, changing the impact angle

Composition of impact resistant strip:

Wear resistant materials: imported natural rubber, synthetic rubber, high wear resistant carbon black. Steel structure: 5mm Q235 one-time formed steel profile

number | Model (width x height x length mm) |

1 | 100 × 100 × 800 (any length within) |

2 | 150 × 150 × 2600 (any length within) |

3 | 200 × 200 × 2600 (any length within) |

4 | 250×250×2600(any length within) |

5 | 300×300×2600(any length within) |

Note: If the area to be protected is not tightly attached to the rock foundation, holes should be drilled at the protection point and bolted to the impact resistance. If the protection point cannot be drilled, the impact resistance strip can be installed on a steel plate or conveyor belt and suspended from a high place to the protection point