- Product

-

Wear resistant protection series

-

Emulsion cleaning reduction reaction series

-

Flat silicone sealant series

-

Cable quick wear-resistant repair adhesive

-

Licheng Series

-

Lixin Intelligent Fog Forest System

-

Conveyor Belt Rapid Processing Series

-

Emergency series of leaks and spills

-

High temperature resistant protection series

-

Protective shield

Contact Us

Shanxi Beiguo Science And Technology Co., LTD

Business Consultation:+86-0354-3965688

Address: Yuci Industrial Park, Jinzhong City, Shanxi Province

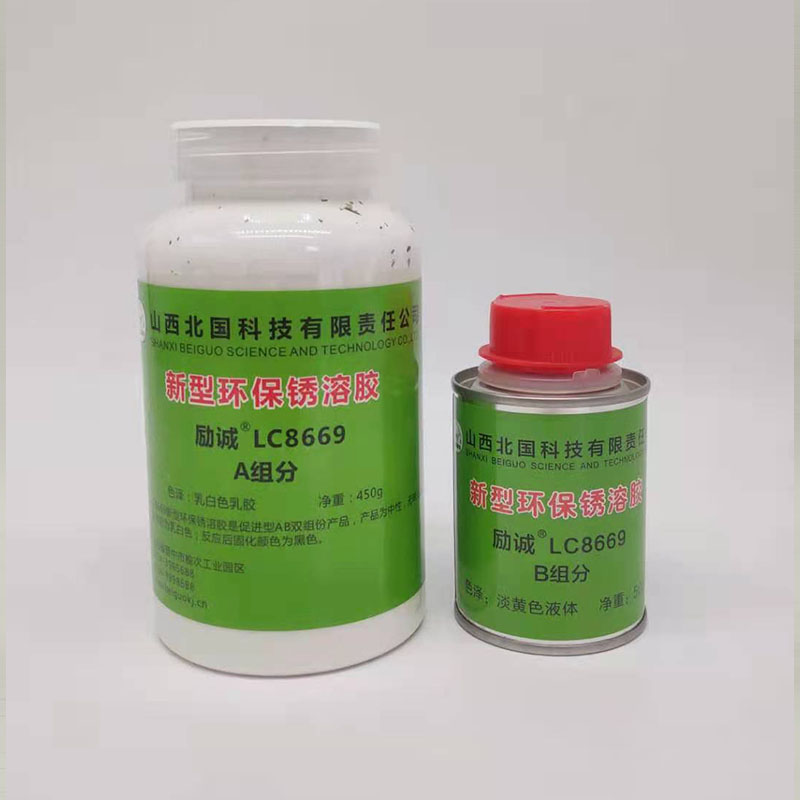

product name:New environmentally friendly rust sol

origin:

application:Model: Licheng LC8669

Appearance: Milky white latex

Packaging specification: 500g/set, 10 sets/piece Storage period: 12 months

sales hotline:+86-0354-3965688

Features: LC8669 new environmentally friendly rust sol is a promotion type AB two-component product, which is neutral, odorless and non irritating. Color: milky white before reaction; The cured color after reaction is black.

Application: LC8669 is an environmentally friendly new rust sol that is neutral, odorless, and non irritating. It does not require polishing and can be directly brushed onto corroded conveying pipelines, equipment base surfaces, feet, color steel room panels, channel steel, angle steel, factory handrails, and guardrails. The rust powder particles on the base surface are reduced to iron powder, and combined with the adhesive properties of LC8669, a protective film is formed on the surface to prevent secondary corrosion of metal components by oxygen, water, and carbon dioxide, thereby achieving the effects of rust removal, rust prevention, and sealing. If lighting treatment is required, the product can be directly used as a primer after curing, without polishing, and can be directly sprayed with paint.

Product parameter table:

Index | Component A | B component |

ph value | 3 | 6 |

Solid Content | 40±1% | 18% |

Product ratio: 9:1 | 450g | 50g |

Surface drying time | 25-35 minutes | |

Storage period | 9 months | |

Storage temperature | 0-36 degrees | |

usage method:

1. Pour the AB components of the product into a mixing cup as needed, and stir thoroughly with a mixing knife until uniform and color free. 2. Use a shovel to remove any foreign objects on the surface first.

3. Use a brush or roller dipped in glue to evenly apply it to the area to be treated.

4. The prepared product should be used up within 30 minutes, otherwise gel will appear and affect the use effect of the product. After 45 minutes of product brushing, if the surface colloid completely turns black, it indicates that the product has completed reaction curing,

Topcoat spraying can be carried out.

matters needing attention:

After the product solidifies, it will change color when exposed to water, and the color will recover after drying.

2. The cross grid method is used for testing, and the adhesion of the cured product is level 1.