- Product

-

Wear resistant protection series

-

Emulsion cleaning reduction reaction series

-

Flat silicone sealant series

-

Cable quick wear-resistant repair adhesive

-

Licheng Series

-

Lixin Intelligent Fog Forest System

-

Conveyor Belt Rapid Processing Series

-

Emergency series of leaks and spills

-

High temperature resistant protection series

-

Protective shield

Contact Us

Shanxi Beiguo Science And Technology Co., LTD

Business Consultation:+86-0354-3965688

Address: Yuci Industrial Park, Jinzhong City, Shanxi Province

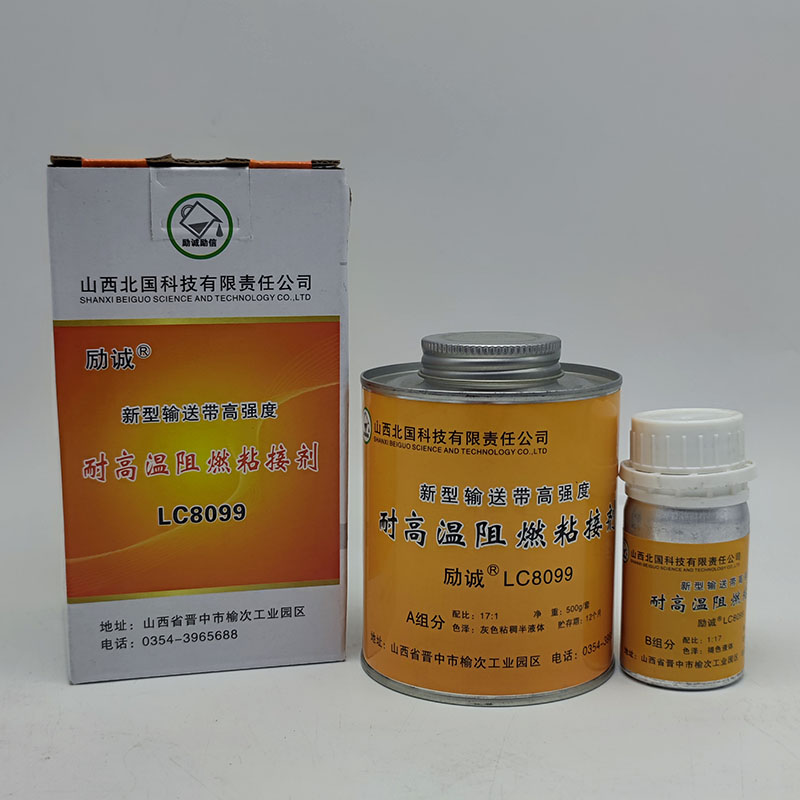

product name:New type of high-strength, high-temperature resistant, flame-retardant adhesive for conveyor belts

origin:

application:Model: Licheng LC8099

Appearance: Black viscous semi liquid

Packaging specification: 500g/set, 12 sets/piece

Storage period: 12 months

sales hotline:+86-0354-3965688

This product is composed of A/B two-component, flame retardant, and more convenient and safe for storage, transportation, and use. Quickly cure and bond at room temperature and pressure. After bonding, let it stand for 60 minutes to operate under load. Colloids are resistant to water, oil, acid and alkali, aging, and weather, suitable for bonding and repairing conveyor belt joints and conveyor belt repair strips used for transporting materials at room temperature.

parameter | unit | Performance at room temperature after 1 hour | High temperature performance at 150 ℃ after 8 hours |

density | g/cm³ | 1.30 | |

peelstrength | ≥N/2.5cm | ≥100N | ≥80N |

shear strength | ≥MPa | ≥2.3 | ≥1.8 |

Viscosity | Pa.s | 2.0 | |

nonvolatile content | % | ≥13 | |

combustibility | Self extinguishing/flame retardant type | ||

Temperature | Celsius | ≤150℃ | |

Operating time | 15min | ||

usage method:

1. Cut, roughen, and remove slag from the joint according to the process requirements. Use LC8665 high-efficiency cleaning agent for surface cleaning;

2. Pour the adhesive of component A into the mixing cup, and then pour the curing agent of component B into the mixing cup. Use a mixing knife to stir evenly in a clockwise direction, and brush the adhesive evenly 2-3 times with a brush. After the first brushing, it needs to be completely dry. During this period, it can be baked with an iodine tungsten lamp or infrared lamp. When the adhesive layer is dry to the point where it is not drawing, it should be immediately bonded. Use an LC8610 roller to repeatedly press the bonding area to eliminate internal bubbles as much as possible;

3. Maintain smooth ventilation in the environment during use;

4. The prepared adhesive should be used up within 15 minutes.