- Product

-

Wear resistant protection series

-

Emulsion cleaning reduction reaction series

-

Flat silicone sealant series

-

Cable quick wear-resistant repair adhesive

-

Licheng Series

-

Lixin Intelligent Fog Forest System

-

Conveyor Belt Rapid Processing Series

-

Emergency series of leaks and spills

-

High temperature resistant protection series

-

Protective shield

Contact Us

Shanxi Beiguo Science And Technology Co., LTD

Business Consultation:+86-0354-3965688

Address: Yuci Industrial Park, Jinzhong City, Shanxi Province

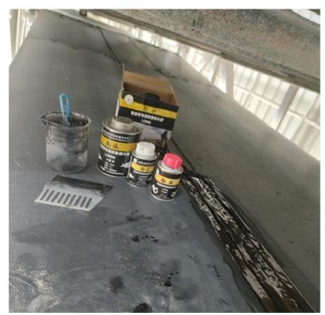

product name:Quick wear-resistant repair adhesive for conveyor belt

origin:

application:Licheng LC8600

sales hotline:+86-0354-3965688

1、 Characteristics

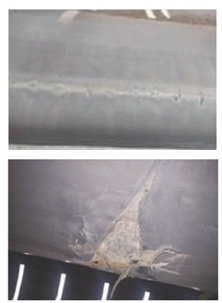

Licheng LC8600 conveyor belt quick wear-resistant repair adhesive is a specialized cold repair adhesive for various conveyor belts. It has the characteristics of fast curing at room temperature, strong adhesion with conveyor belts, high tensile strength, high tear resistance, good wear resistance, impact resistance, high temperature resistance, flame retardancy, etc. It is commonly used for aging repair of working layers of strong coal mine belts (main shaft belts); The belt buckle at the joint of the conveyor belt is wrapped with glue;

Corrosion prevention repair of exposed steel wire rope; Repair of non working layer after tearing of conveyor belt; Repair the sealing of the conveyor belt after excavation and repair; Partial penetration repair of conveyor belt; Repair the sealing of the joint after cold vulcanization bonding of the conveyor belt to prevent dust and moisture from entering the joint and causing it to curl up; Carbonization repair of high-temperature conveyor belt; Repair of defects and leaks in the outer frame of the polyurethane sieve plate.

2、 Performance

Curing time (at room temperature), min | >10 | |

Adhesive strength with conveyor belt | Peel strength, Kg/cm ² | >20 |

Shear strength, Kg/cm ² | >50 | |

Tensile strength, MPa | >20 | |

Tear strength, KN/m | >70 | |

Elongation rate,% | >400 | |

Impact elasticity,% | 25 | |

Hardness, Shore A | 70-80 | |

temperature resistance | Within 150 ℃ | |

Running time of repaired conveyor belt | 0-10℃,h | 2.3 |

10-15℃,h | 1.8 | |

15-20℃,h | 1.2 | |

20-35℃,h | 0.8 | |

Repair quantity | 1.8mm thickness | 1 square meter per set |

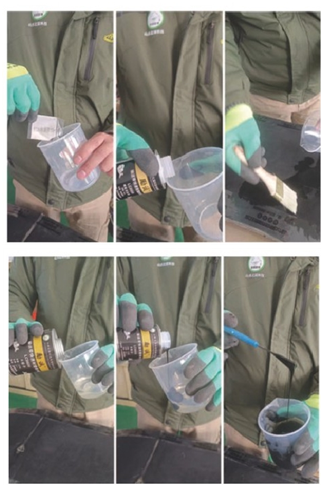

3、 Usage method

1. First, move the damaged part of the conveyor belt to a horizontal position, use the tool knife inside the box to remove the non adhesive part of the damaged part of the belt, and use an angle grinder to polish a new layer of the area to be repaired, removing dust, water vapor, and oil stains.

2. Pour an appropriate amount of component D into a mixing cup, add an appropriate amount of component C (35:1), dissolve component D completely, dip a glue brush in the activator solution, evenly brush and apply it to the area to be repaired to dry, and then apply it again to dry. Repeat several times for better results.

3. (1) Repair the worn/carbonized/aged working layer: After the activator has fully reacted, fully seal and paste the tape inside the box along the polished area brushed with activator. Then open the repair glue can cover and pour component A and component B into the mixing cup according to the weight ratio. Use a mixing knife to quickly stir clockwise for 1-2 minutes. After stirring evenly, pour the glue into the sealed area of the tape.

Use a scraper inside the box to level the rubber material as much as possible with the belt. After waiting for the adhesive to react for 10 minutes, remove the tape and allow the adhesive to self chamfer, making it easier for the cleaner to pass through without obstacles.

(2) Repair through damaged conveyor belt: If there is a small area of penetration and it does not affect the strength of the conveyor belt, the through area can be completely adhered with tape inside the box in the non working layer to prevent the loss of adhesive material. After the activation agent of the working layer has fully reacted, use the tape inside the box to fully seal and paste the polished area coated with the activation agent along the working layer. Then open the repair glue can cover and pour all components A and B into the mixing cup. Use a mixing knife to quickly stir clockwise for 1-2 minutes until evenly mixed. After stirring evenly, pour the glue into the sealed area of the tape and use a scraper inside the box to scrape the glue as flat as possible with the belt. After waiting for the adhesive to react for 10 minutes, remove the tape and allow the adhesive to self chamfer, making it easier for the cleaner to pass through without obstacles.

(3) Repair the damage caused by the penetration of the canvas conveyor belt: If the penetration area is large and affects the strength of the conveyor belt, first polish the non working layer of the canvas conveyor belt to the canvas layer. Then, use LC8606 repair strip and LC8088 (room temperature flame retardant adhesive)/LC8099 (high temperature flame retardant adhesive) to fully bond the penetration area longitudinally to the area to be repaired. Use LC8610 pressure roller to repeatedly roll the bubbles generated by the adhesive reaction at the repair area until they are completely discharged. Finally, evenly brush the activator on the filling area. After the activator fully reacts, seal and paste the filling area with tape. Then open the repair glue can cover and pour both component A and component B into the glue mixing cup. Use a glue mixing knife to remove the bubbles. Stir clockwise quickly and evenly for 1-2 minutes. After stirring evenly, pour the adhesive material into the sealed area of the tape, Use a scraper inside the box to level the rubber material as much as possible with the belt. After waiting for the adhesive to react for 10 minutes, remove the tape and allow the adhesive to self chamfer, making it easier for the cleaner to pass through without obstacles.

After the adhesive material to be repaired has cured for 30 minutes, the conveyor belt can run at low speed to transport the working layer to a convenient surface for operation. Refer to the repair method for worn working layers for repair.

(4) Repair the penetrating damage of the strong conveyor belt: If the penetrating area is large and affects the strength of the conveyor belt, first polish the non working layer to the new adhesive part and polish it flat. Then, use LC8606 repair strip and LC8088 (room temperature flame retardant adhesive)/LC8099 (high temperature flame retardant adhesive) to fully bond the penetrating area longitudinally to the area to be repaired on the non working layer. Repeat rolling with LC8610 roller to completely discharge the bubbles generated by the adhesive reaction in the strong repair strip of the conveyor belt.

Then evenly brush the activator onto the filling area. After the activator has fully reacted, seal and paste the filling area with tape. Then open the repair glue can cover and pour both component A and component B into the mixing cup. Use a mixing knife to quickly stir clockwise for 1-2 minutes. After stirring evenly, pour the glue into the sealed area of the tape and use a scraper inside the box to scrape the glue as flat as possible with the belt. After waiting for the adhesive to react for 10 minutes, remove the tape and allow the adhesive to self chamfer, making it easier for the cleaner to pass through without obstacles.

After the adhesive material to be repaired has cured for 30 minutes, the conveyor belt can run at low speed to transport the working layer to a convenient surface for operation. Refer to section 3.1 for repair methods for working layer wear.

Please refer to the performance table for the operating time after repairing the conveyor belt.

4、 Precautions

1. If it is inconvenient to find the repair area of the conveyor belt, when using a glue adjustment knife to adjust the glue, the mixing time can be extended in the glue adjustment cup until there is resistance to the mixed glue material, and then poured to the repair area and scraped flat with a scraper.

2. LC8600 conveyor belt quick wear-resistant repair adhesive is a reactive material that is very sensitive to water. Once the AB component is turned on, it cannot splash water, otherwise it will foam and affect the quality of belt repair.

3. The product should be stored in a room with heating during winter. If storage conditions do not allow, the product may crystallize if the temperature is too low. Before use, it should be heated in hot water to remove crystallization before use.

4. When the ambient temperature is below 0 ℃, the curing time of the repair adhesive will be longer. To avoid affecting the startup time, component A of the repair adhesive can be heated appropriately (hot water, electric heating plate, hair dryer can all be used) before use, and the heating temperature should not exceed 60 ℃.

5. When waiting for complete curing time and needing to be turned on urgently, a hair dryer, small sun, or iodine tungsten lamp can be used to heat up half a meter away from the repair site, which can effectively promote the reaction and accelerate the curing time appropriately. However, small bubbles may appear on the surface of the repair site, affecting the appearance but not particularly affecting the repair adhesive indicators.

6. The glue adjusting knife and cup can be peeled off and reused after the repair glue is completely cured.

7. The tool knife inside the box is very sharp, please pay attention to safety when using it! The tool knife is only used for repairing conveyor belts, and any accidents that may occur during use are not related to our company!