- Product

-

Wear resistant protection series

-

Emulsion cleaning reduction reaction series

-

Flat silicone sealant series

-

Cable quick wear-resistant repair adhesive

-

Licheng Series

-

Lixin Intelligent Fog Forest System

-

Conveyor Belt Rapid Processing Series

-

Emergency series of leaks and spills

-

High temperature resistant protection series

-

Protective shield

Contact Us

Shanxi Beiguo Science And Technology Co., LTD

Business Consultation:+86-0354-3965688

Address: Yuci Industrial Park, Jinzhong City, Shanxi Province

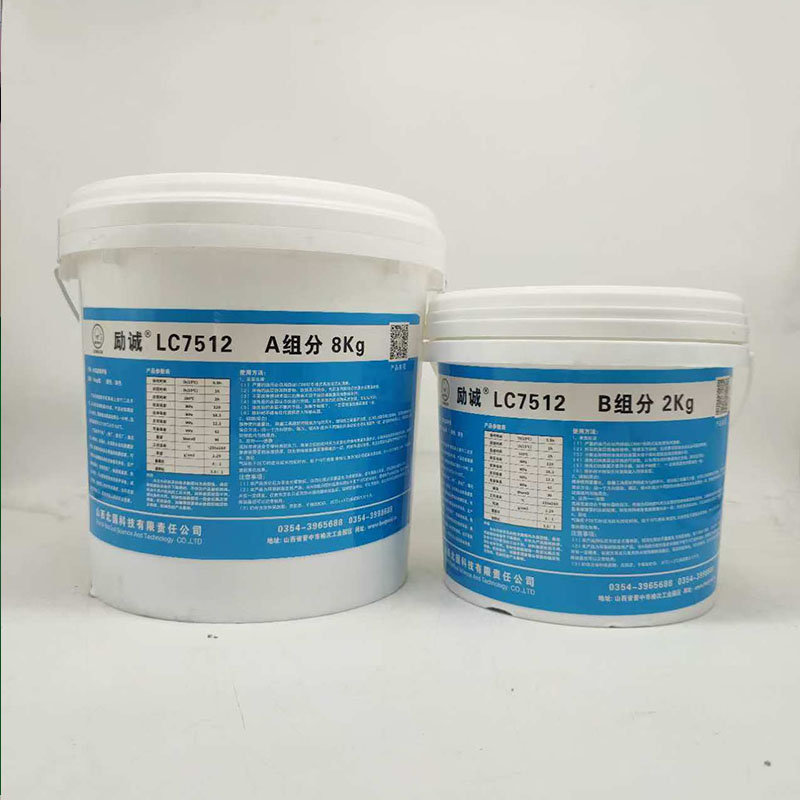

product name:High temperature resistant large protective shield

origin:

application:Model: Licheng LC7512

Color: A gray B black

Proportion: weight ratio (4:1), volume ratio (3.5:1)

Packaging specification: 10kg/set

Storage method: Store in a cool, dry place.

Shelf life: 12 months at 20 ℃ (± 5 ℃)

The product has undergone secondary development based on the Licheng protective shield and can achieve long-term temperature resistance of 260 degrees. After curing for 1 hour in the early stage, the product needs to be cured at a high temperature for another hour, and the temperature should be greater than 100 ℃ and less than 150 ℃. The product is suitable for wear-resistant and corrosion-resistant flue gas ducts, desulfurization and denitrification equipment, and pipelines in power plants, steel mills, coking plants, alumina, monocrystalline silicon, polycrystalline silicon, cement and other enterprises. It can effectively extend the service life of equipment in areas prone to wear and tear, and the product is easy to operate, widely applicable, with high bonding strength and short curing time. It can protect equipment faster and more effectively, reduce the labor intensity of maintenance and inspection personnel, and effectively reduce the occupational hazards of welding workers and high-altitude workers.

sales hotline:+86-0354-3965688

Operating time (h/25℃) | Initial solidification time (h/25℃) | Post solidification time (h/100℃) | Compressive strength (Mpa) | Tensile strength (MPa) | Shear strength (MPa) | Bending strength (MPa) | hardness (ShoreD) | Working temperature (℃) | density (g/cm³) |

0.5 | 1 | 2 | 120 | 38.3 | 12.3 | 61 | 90 | -25-260 | 2.29 |

usage method:

(1) Surface treatment

a) Serious oil stains must be cleaned with Licheng LC8667 self spraying high-efficiency cleaning agent;

b) All surface free attachments, rust, and pollutants, including residual coatings, must be removed;

c) Do not apply repair agents directly to the surface after rust removal without drying treatment;

d) The cleaned surface should be coated as soon as possible to avoid rusting, oxidation, or contamination again;

e) Do not touch the cleaned surface with your hands. If touched by hand, be sure to clean it again with cleaning agent;

f) No liquid shall enter the surface to be repaired during the repair process.

(2) Modulation (Hybrid)

It is recommended to use a weight ratio, and it is best to use a balance with an accuracy of 1g for weighing tools. On site construction weighing is inconvenient, and it is also possible to visually determine the volume ratio for preparation, in order to obtain materials as accurately as possible.

Mixing method: Stir and roll in one direction to completely eliminate the stripes of different colors of A/B components until the colors are consistent and the colloid is stirred smoothly, which means that thorough and uniform mixing must be ensured.

(3) Application - Coating

Choose a scraper with a width suitable for repairing the surface, and repeatedly apply the mixed adhesive back and forth on the surface to be repaired with force to ensure that the surface is completely soaked with the adhesive. If a thick coating is required for the surface to be repaired, first apply a thin layer on the surface to be repaired, then apply layer by layer and compact the adhesive layer to avoid air residue and bubble formation.

(4) Curing

When the temperature is below 25 ℃, the curing time should be appropriately extended. It will be difficult to cure below 10 ℃. Heating curing can improve the performance of the coating. Keeping at 100-120 ℃ for 2 hours can achieve the most satisfactory curing effect.

matters needing attention

(1) This product is a safe and non-toxic substance after curing, but it should be avoided from contact with the skin as much as possible before curing. If it accidentally splashes into the eyes, it should be quickly rinsed with plenty of water.

(2) This product is a modified epoxy resin product. When the temperature of the A/B component adhesive is kept below 15 ℃ for a long time, the colloid will undergo crystallization, such as solidification, and have a certain hardness. In the south, as long as the crystallization is released by preheating with hot water, the viscosity will decrease, and it can be used normally; In the north, it can be placed on the heater in advance and can be used normally after the crystallization is released.

statement

The technical data mentioned in this article are typical values obtained under laboratory standard conditions and are not used as product acceptance criteria. However, due to different working conditions used by users, the surface state of materials and curing conditions are different, and some changes in actual performance data are normal phenomena. Storage conditions, transportation, and other factors can all affect the stability, physical and mechanical properties of the adhesive.